It’s an incredible machine. As well as the obvious economic benefits, it’s much cleaner than the aircraft it replaces, produces far less CO2 and has a much smaller noise footprint. This is an aircraft that has been built from the ground up using the latest durable, light materials coupled with an advanced aerodynamic design. And finally, it’s powered by the incredible Rolls Royce Trent XWB engine, more of which later on.

There are so many reasons to love our new Airbus A350. The lush new cabins. The huge TV screens. The spacious interior, and the numerous little touches we’ve designed and added just for you. But equally impressive are some of the unseen innovations, because the A350 is the quietest and most economical long haul jet ever built.

Materials

Seventy per cent of the A350’s airframe is made of advanced materials including 53% composites, which are lighter and more robust than those used on previous aircraft designs. Airbus uses something called CFRP, which stands for carbon-fibre reinforced plastic, made from carbon fibres bound with plastic resin. It’s lighter than aluminium, stronger than iron, and more corrosion resistant than both. CFRP is used for the wings, the centre wing box and keel beam, tail cone, skin panel, frames and doors, while the door surroundings, landing gear, engine pylons and high load frames are made of titanium. All together, this makes for a light and fuel-efficient aircraft which is much less prone to fatigue and corrosion, and easier to maintain. The wings, made in Broughton in Wales, are 32 metres long, six metres wide and the largest single aircraft part made from carbon composite material.

Aerodynamics

Talking of the wings, they play a massive part in the aerodynamic gains in the A350 design. What makes them so special is the way they’ve been designed to morph in flight, changing shape for maximum aerodynamic efficiency throughout the different phases of the journey. Airbus calls this biomimicry, an innovative design approach that borrows cues from nature such as bird wings that have evolved over millennia, changing form to give maximum lift and minimum drag. The wing design includes several other streamlined features (warning, this gets a bit technical now) such as droop-nose leading-edge devices and new adaptive dropped-hinge flaps, which increase efficiency at low speeds.

To improve efficiency at higher speeds, the A350 XWB can deflect its wing flaps differentially, optimising the wing profile and providing better load control. More gains are made using myriad little touches like refining the shape of some of the fairings, using curved windshields and low drag engine nacelles. These, and many other small design modifications such as filled flap side edges, help the wing slip through the air better and keep the noise down.

Those giant engines

When it comes to efficiency, you’d be forgiven for thinking the more streamlined the better. This works in most places but not the engines. The Rolls Royce Trent XWB engines that power the A350 are enormous. So large, in fact, that the fuselage of Concorde would fit inside one. The Trent family of engines first appeared in 1990 and over several different variants have flown for millions of hours since. The Trent XWB is the latest iteration of the range. As well as borrowing from its Trent family inheritance, it incorporates the latest in engine technology to give a cleaner burn, better reliability and lower fuel consumption.

The secret to building an efficient jet engine is something called bypass ratio. That massive fan at the front of the jet engine only funnels a small amount of the air it gulps into the turbines, where it mixes with fuel and ignites. The vast majority of the air sucked in by those huge blades bypasses the main engine, goes round the outside and rejoins the heated, compressed and ignited air at the back of the engine. That’s why, if you look at an engine, for a large part, you can see straight through from front to back. This achieves two things. It gives the aircraft more thrust for your money (but only if you are flying below the speed of sound) and it acts as a blanket around the engine to keep the noise down. If you go back in time and look at the airliners of the 1960s and 70s, you’ll see the engines were much narrower. They had very low bypass ratios and as a result, were noisy and thirsty beasts. Over the years the size of those first stage fans has grown – as has the percentage of bypass gas – to the point today where the A350 Trent XWB engine is a true giant, and the bigger the engine, the more efficient and quiet it is.

But that’s not the only incredible stat about this engine. At take-off, each engine sucks up to 1.3 tonnes of air every second, about the equivalent of a squash court full of air. The turbine blades inside the engine rotate at 12,500 rpm, with their tips reaching 1,200mph, with a force equivalent of nine London buses hanging off each blade. Whoosh indeed.

Shhhh….

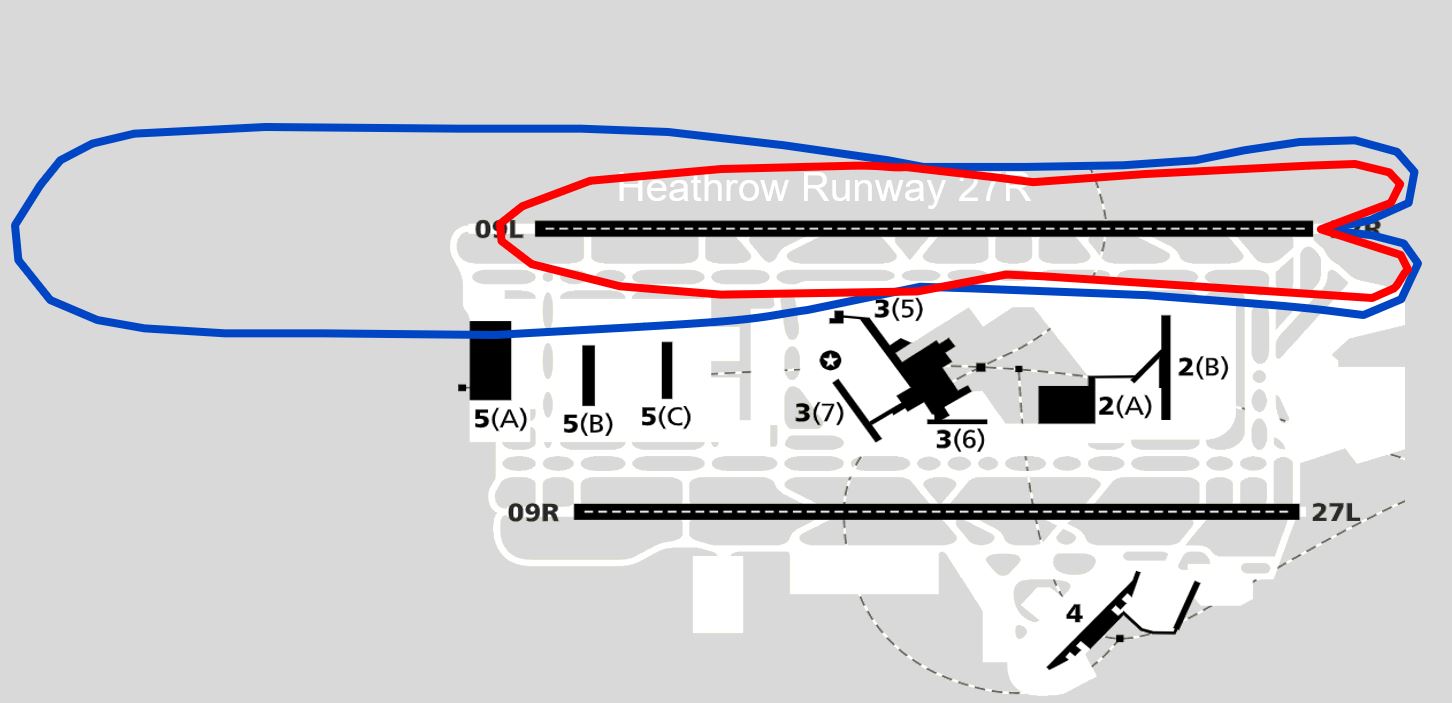

The high bypass engines and smooth aerodynamics mean that as well as being economical the A350 is the quietest long haul aircraft in the sky. This is good news for our customers relaxing onboard. An article we read recently claimed you can leave those fancy noise-cancelling earphones at home, and with a cabin that is up to nine decibels quieter than older generation aircraft, we’re not surprised. Just as importantly, the A350 is also super quiet on the outside, which is significant for anyone who lives near, or works at, an airport. To illustrate just how quiet the A350 is, the map below shows the area where an aircraft is departing and the noise of it on the ground is perceived to be higher than 85 decibels. The A350 footprint is 52% smaller than that of the 747-400.

The red A350 noise footprint at Heathrow compared to the blue 747

When you combine the design and technology that Airbus have put into the build of the A350 with the efficiency of the Rolls Royce Trent XWB, you get the quietest, most efficient wide body long-haul aircraft in the skies. That’s why the Airbus A350 plays a crucial role in our fleet transformation strategy, which states that by 2022 we’ll have the youngest, cleanest, greenest fleet in the industry.

Our first Airbus A350-1000s are now flying from London Heathrow to New York. Book your flight at VirginAtlantic.com and read about our sustainability programme here.