Max Longhin is one of our flight service managers. Born in the small town of Ivrea in northern Italy, Max spent his school years in South Africa before moving to the UK in 1988. He spent four years pursuing his dream of becoming a fashion designer and worked for several famous fashion houses before starting his own label and boutique. After becoming disillusioned with the world of fashion, he couldn’t help but notice how much fun his cabin crew flatmates seemed to have at work. A quick career change, and following a few years with other airlines Max joined Virgin Atlantic. That was 30 years ago and since then he’s never lost his love of flying or his passion for Virgin Atlantic.

Despite a fabulous career in the air, Max still keeps in touch with the fashion world, hasn’t lost his eye for a bit of fashion detail and still maintains the skills he learned as a designer. As the first lockdown began Max put his skills to good use. While on furlough he joined a Facebook group called ‘For The Love Of Scrubs’ and set to work making scrubs for our NHS workers.

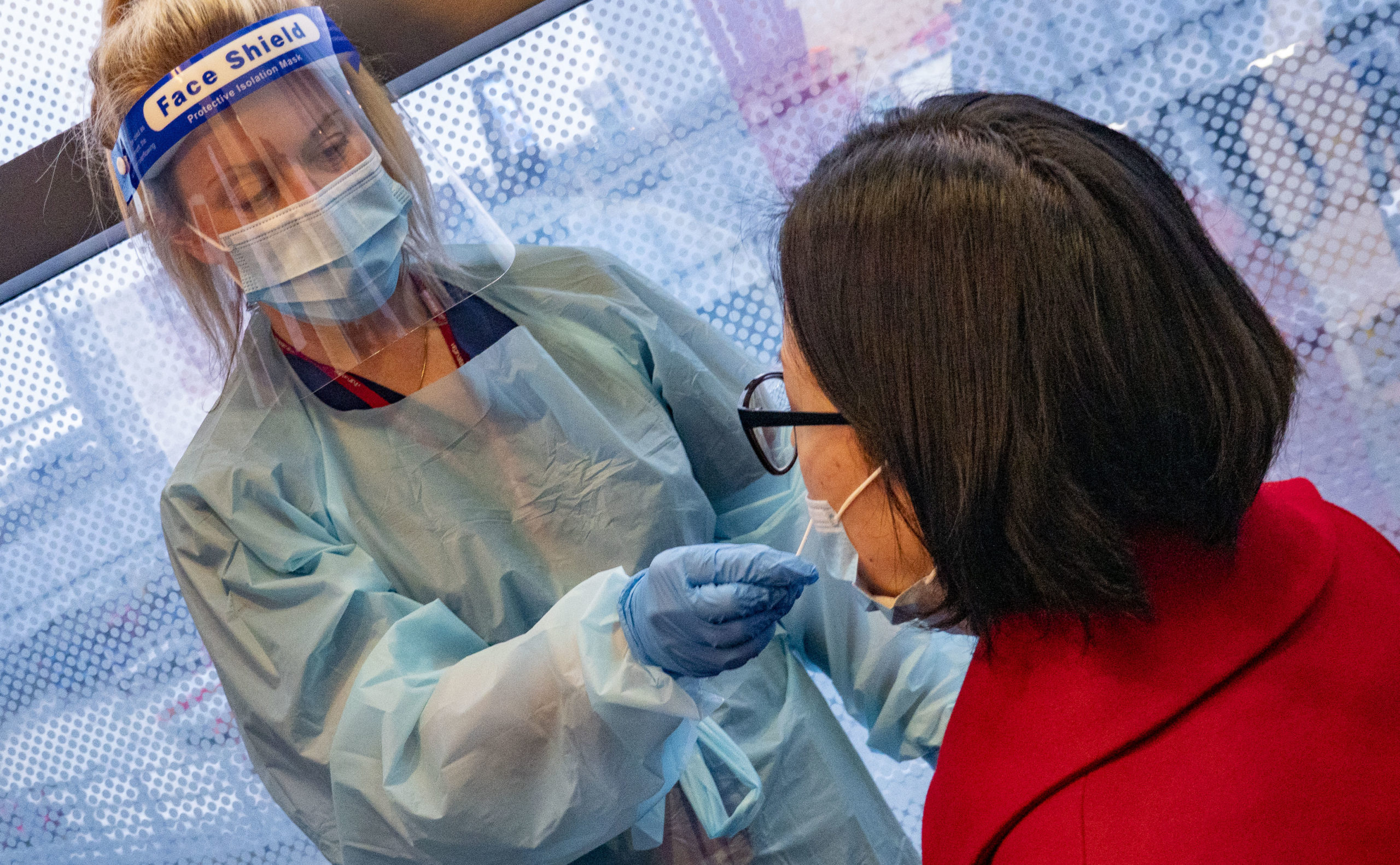

Once back at work after furlough, Max went to the Upper Class Wing to be tested ahead of his first flight. That’s when the fashion designer in him immediately spotted a problem. “I noticed that the scrubs were all badly fitted, they had no pen pockets, and their hems were taped up or dragging. At the time, scrubs were in short supply, so they were making do with what they could find” said Max. “My first thought was ‘what can I do to help?’ so I decided to set up an alteration service for the team”.

After that, Max decided to go one better and create bespoke fitted designer scrubs for the testing team. Surely the finest scrubs in the land.